- Home

-

Products

- Case Solution

- Download

-

About Us

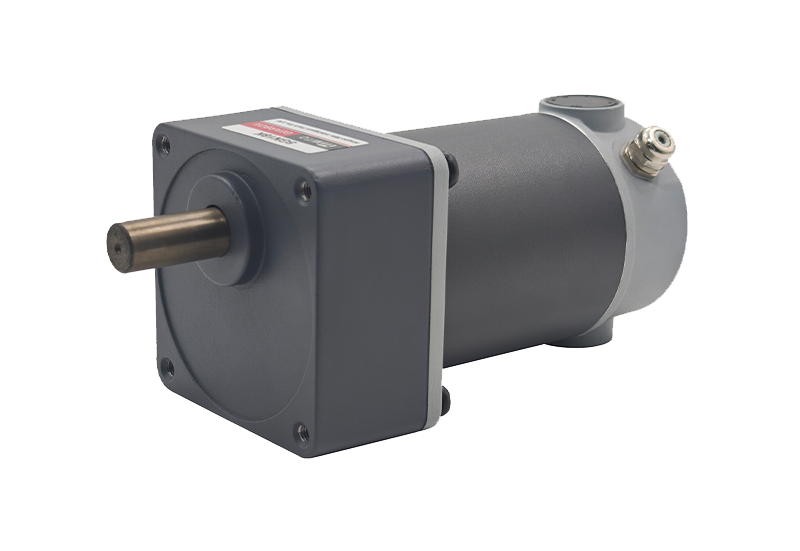

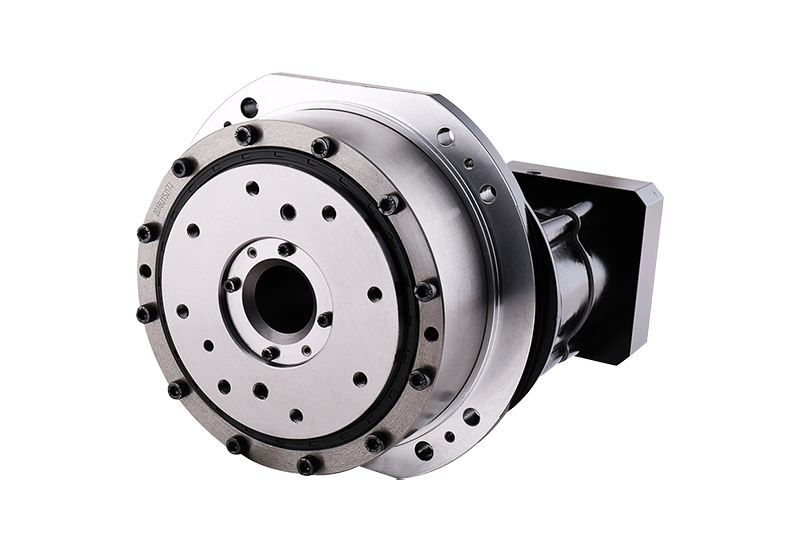

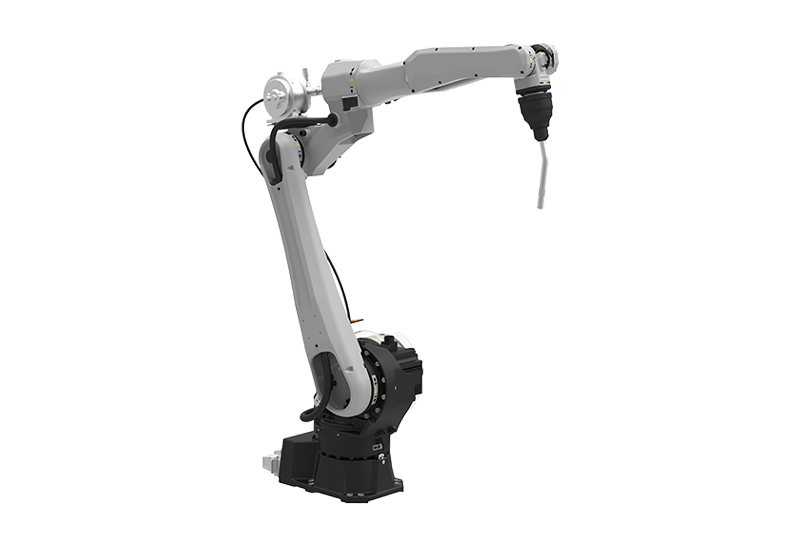

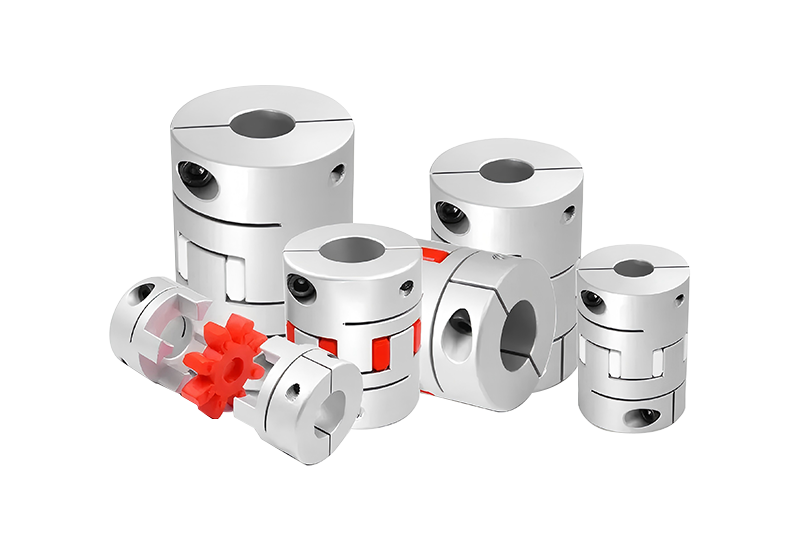

Why Choose Us?Ningbo Mito Intelligent Technology Co., Ltd., along with its subsidiary Suzhou Mito Intelligent Equipment Co., Ltd., is a leading provider of industrial automation solutions specializing in the sales and customization of high-performance motion control products. With years of deep-rooted expertise in the automation industry, we are committed to delivering innovative, reliable, and efficient solutions to clients worldwide.

Coming From China, Marketing To The World.

Coming From China, Marketing To The World. - News

- Contact Us